FIJI Sugar Corporation board paper from October 2018 made public this week reveals the negative financial impact on FSC through the Sugar Technology Mission of New Delhi – India (STM) mill upgrade. Prepared and signed off by then FSC chief executive officer Graham Clarke and chief financial officer Manoj Kumar, the FSC board paper states “the STM project failed to deliver its objectives”.

The board paper states Fiji Sugar Corporation executive team submitted a detailed proposal in 2003 for the upgrade of the four mills in Lautoka, Rarawal, Labasa and Penang. The proposal covered the upgrade of the four sugar mills amounting to $220million. FSC finally opted for an alternative submission by the Sugar Technology Mission of New Delhi – India (STM) which offered to do the proposed factory upgrades for three factories (Lautoka, Rarawal and Labasa) for half the cost of $115million ($US50.4million). The FSC board paper states on August 18, 2005 the chairman of the Fiji Sugar Corporation Ltd, Ross McDonald on behalf of the corporation authorised Mr J.J. Bhagat, the head of STM to issue and receive tenders on behalf of the corporation for the purpose of technology upgrade and process modification at Lautoka, Rarawal and Labasa mills. The FSC board paper adds the tender, bid, evaluations, approvals and appointment of vendors were carried out by Mr J.J. Bhagat, the head of Sugar Technology Mission Projects Ltd and funding from EXIM Bank of India was secured.

The STM project

The FSC board paper categorically states: “The STM project failed to deliver its objectives. Executing all the scope of work covered in the initial FSC proposal of $220million, at half the cost $110million for the three factories was not possible,” stated then FSC CEO Graham Clarke and chief financial officer Manoj Kumar in the board paper.

They stated this resulted in cheap or inferior quality equipment and materials being supplied by some vendors.

“The supervision of erection of the supplied equipment was very poor. Likewise poor-quality workmanship was carried out by the sub-contractors that were engaged by the vendors. Poor project management failed to resolve this, Moreover, modifying and converting existing equipment or vessels designed for exhaust steam, to accommodate new Indian technology of energy efficiency through vapour bleeding and maximum exhaustion was costly and not fully installed,” states the FSC board paper.

The board paper adds Fiji Sugar Corporation subsequently improved operations in these areas over the years after the STM project closed, but at a very high cost.

“The head of the Sugar Technology Mission, Mr J.J Bhagat formed a company STMPL (Sugar Technology Mission Projects Ltd) and was given sole approval to issue and receive tenders and appoint the successful bidders on behalf of FSC,” the board paper reads.

Mr Bhagat was also appointed the engineering consultant and project manager of the STM projects.

“Project management was ineffective and a dismal failure. One Individual had total control over the project with no transparency, checks and balances. As mentioned In the Systems Consultant Report, it is very surprising that most reputed Indian manufacturers of complete sugar plants known for their quality and workmanship have not taken part in the bids,” states the FSC board paper.

The FSC board in 2018 were told there was a lack of co-ordination between the Project Manager in India, his STMP team on site, the vendors, their sub-contractors and the FSC team.

“A lot of grey areas were encountered during the implementation of the STM project which caused delays and uncertainties. These issues should have been sorted out or covered during the preparation of the project contracts before the execution of the projects,” said the FSC board paper.

“Surprisingly no further action was taken by FSC management once these failures had emerged. Further, FSC did not appoint a technically qualified engineer to supervise the project and ensure delivery according to FSC requirements. Full reliance on STMPL was inappropriate and did not deliver the required level of engineering supervision.”

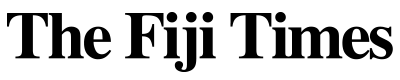

Financial impact on FSC at May 31, 2010

$75.6million, which was funded by EXIM Bank of India was cost of supply, installation and commissioning of plant and equipment, while it cost Fiji Sugar Corporation a further $43million to complete local works as required.

“As such total cost of the STM project was $118.7million,” states the FSC board paper. Over and above off-season rectification works captured under mill operating costs, FSC subsequently spent F$4,423,846 on capital works to improve performance of the plant and equipment supplied under the STM project. The FSC board in 2010 were informed as a direct result of poor STM upgrade implementation and subsequent mill performance, FSC unit operating cost per tonne of sugar increased to an average of $400 between 2008 to 2012 season, compared to below $250 prior to STM.

“This additional cost to FSC over the 5-year period was F$118.9million. Further, tonnes cane to tonne sugar (TCTS) ratio worsen to an average of over 12.0 during the STM upgrade implementation period whilst the target was 8.5. Prior to the upgrade project the TCTS was below 9.7 on average. Consequently, FSC lost around $108.2million as FSC’s share of revenue.”

Cost of hiring Indian

expatriates

The board paper states there was no training program arranged by either by STM projects or the vendors for the transfer of skills and technology for the operation of the new technology or the supplied equipment.

“The consequence was FSC having to employ 40 Indian expatriate plant operators for three years at a cost of $9,205,895 in order to operate the STM plant and equipment. The total annual cost to FSC to hire the 40 Indian nationals was $2.2million in salaries, $152,000 in airline ticket costs, $32,000 in airline tickets for family members of the Indian nationals, $392,00 in taxes, $240,000 for accommodation and $10,000 for taxi and local flights.”

The board paper reveals the highest paid Indian nationals were M.Namplyappan as manager energy project on $140,000 and Leela Ramesh as chief production technologist also on $140,000. There were nine Indian expatriates on $64,000 while the rest of them were on salaries ranging from $44,000 to $54,000 annually.

Further evaluations

The board paper states in view of the non-performance and general failure of the mill upgrade program, various evaluations of the STM factory upgrade project were carried out by three separate consultants namely, System Consultants in 2009, J.P. Mukerjee Associates in 2010 and the National Federation of Cooperative Sugar Factories Ltd (NFCSF) in 2013.

“Based on the evaluation and report done by NFCSF, the Corporation (FSC) in 2013 approached EXIM Bank of India for relief and the release of $US5.38 million. After government-to-government deliberation and FSC’s Interaction with Indian High Commission, the Government of India in 2015 agreed to assist the corporation by re-lending to FSC $US5.38million to carry out corrective engineering and enhancement works on the plant and equipment Installed during the STM factory upgrade program.

Future project planning

Then FSC CEO Graham Clarke and chief financial officer Manoj Kumar stated in the board paper that the STM project was an “extremely costly and destructive process” for FSC.

They stated from the experiences encountered, and for future projects, the project cost and budget should not be the only consideration.

“Engineering and quality standards should be the priority for all project work after a thorough technical study of operations in the factories Is carried out,” states the board paper.

Sound project and contract management is a pre-requisite and the bidding and tender evaluation is now managed and handled by a tender committee appointed by FSC and an FSC appointed Engineering Consultant.

“The project manager should preferably be appointed by FSC in consultation with an appointed Engineering Consultant, all large projects should be supervised and managed by an appointed professional Project Manager and executed by a designated project team under the supervision of an appointed FSC project engineer.”